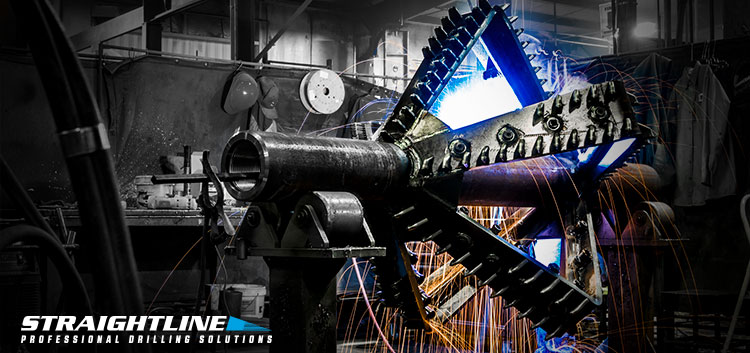

As the decade of the 1990’s began, a handful of companies led the advancement of a new trenchless construction method known as horizontal directional drilling. One of the early pioneers, StraightLine Manufacturing (later to become StraightLine HDD), launched the first of a series of innovative steerable boring machines in 1989.

The market was quick to recognize the nascent technology’s potential. While early demand growth verified the legitimacy of the new technology, it simultaneously exposed a major limitation: Advancements in rig technology far outpaced the development of down-hole tooling.

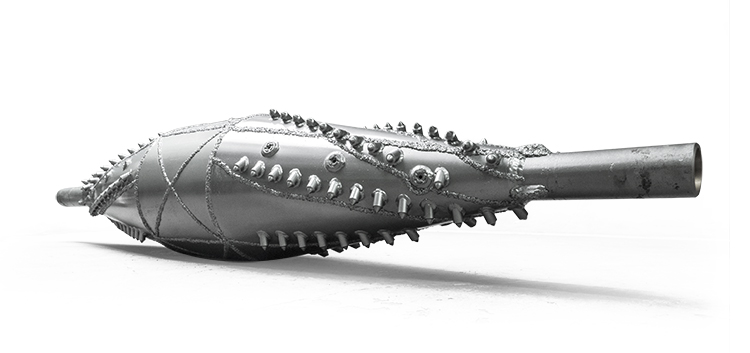

Two early (circa 1991) examples of StraightLine reamers.

Building Reamers By Necessity

StraightLine responded to the lack of available tooling options by building their own. Development culminated in 1990 with the launch of two first-generation reamers.

The success of the initial designs set the stage for a gradual shift away from drill rigs, to focus exclusively on tooling. Today, StraightLine HDD is a leading provider of down-hole tooling. The back reamer segment includes 17 field-proven designs. With hundreds of Vermeer and Ditch Witch reamers in-stock, StraightLine is among an elite few capable of responding with next-day delivery.

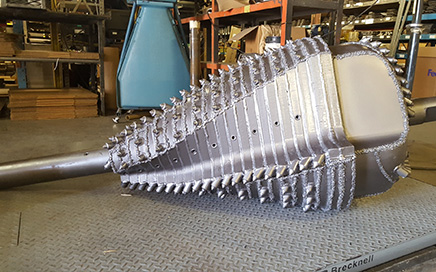

Designed and fabricated in late 2017, this impressive reamer incorporates a steep taper, bi-directional design.

Commitment to Custom Reamer Solutions

The unpredictability of soil conditions often tests “standard” horizontal directional drilling reamer designs. Responding to the challenge, StraightLine HDD maintains a team of designers and fabricators dedicated to building customer-specified reamer solutions.

In 2017 alone, the StraightLine HDD custom reamer team accounted for nearly 70 percent of the company’s reamer revenue output.

From a slightly altered standard design to a completely unique creation, the StraightLine custom HDD reamer team follows the motto: If you can dream it, we can build it.

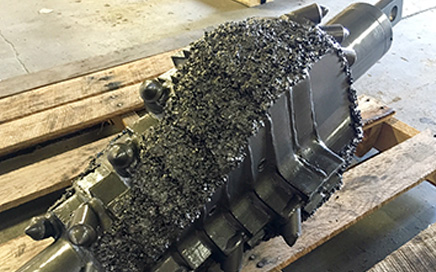

Many custom reamer projects are under tight deadline. This custom fly cutter, for example, was part of a three tool custom job that carried a two-day turn.

To attack extremely abrasive cobble rock conditions, the custom crew used a stacked-plate base design, with slight elongation and a extra application of hard-facing.

On large-scale tool builds, a team approach is used. Here, three members of the custom team collaborate on a massive 46-inch custom all-terrain reamer.

Sometimes, the custom crew creates something that’s completely unique. This massive bi-directional tool is a one-of-a kind reamer.

Is it a hole opener or is it a Rhino? In this case, the customer needed an aggressive hole opener, as well as an aggressive pull-back solution.

This large diameter (42-inches) All-Terrain reamer was finished off with an equally substantial pull-back cap.

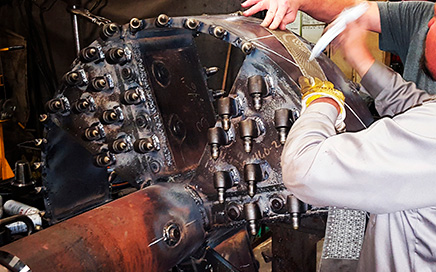

Here, the custom team plots out hard-facing on a substantial centralizing ring. The custom tool features a “flat-face” design with aggressive cutters.

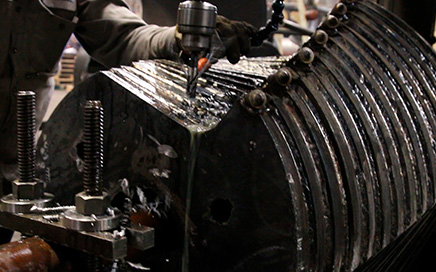

The popular All-Terrain forms the base design for a large number of custom solutions. Here’s a massive custom All-Terrain being drilled for fluid ports.